This test is to find out how many cycles the gas strut can undertake before it stops working.

The test is carried out using a hydraulic machine that goes back and forth in one direction. This test is suitable for gas struts’ shut and open function. In this test, we are seeing if the gas strut can operate up to 40,000 cycles, or 10 years average of usage. This is an average lifespan of gas struts. Calculation is based on:

- 10 times/cycles usage per day x 365 days = 3650 cycles.

- 3650 cycles x 10 years = 36,500 cycles.

- 1 cycle is equal to 1 shut (close) stroke and 1 open (extend) stroke of the gas strut.

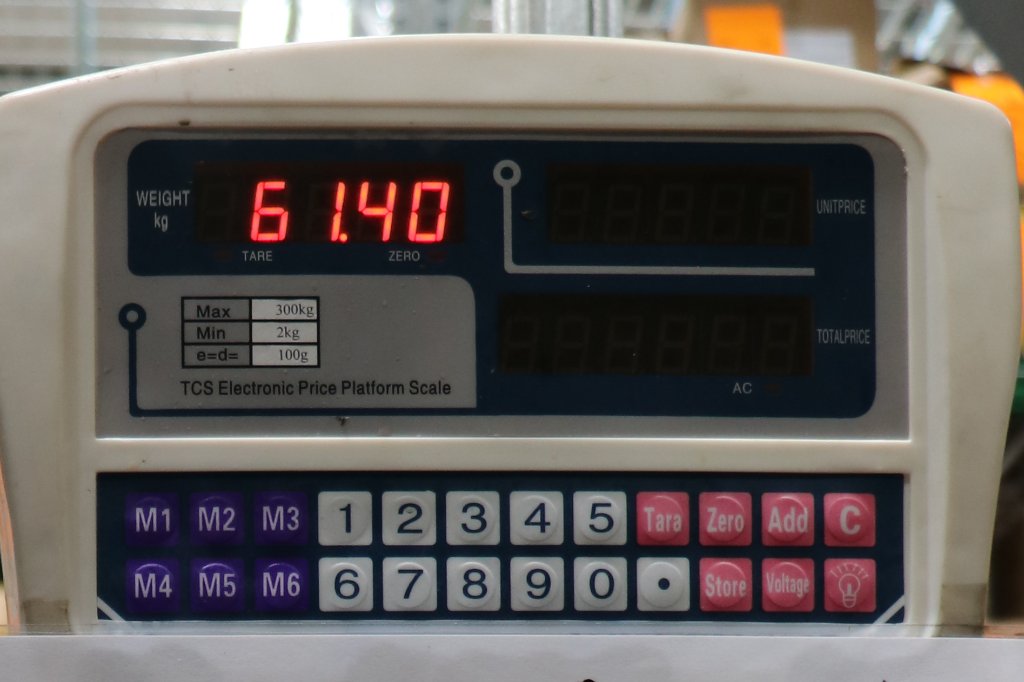

The gas strut had 120kg of gas pressure but for this test it is reduced to 65kg for initial data. The test is set up by fitting one end of the strut in a fixed position and the other attached to the machine. The machine pushes and pulls the strut, opening and closing it.

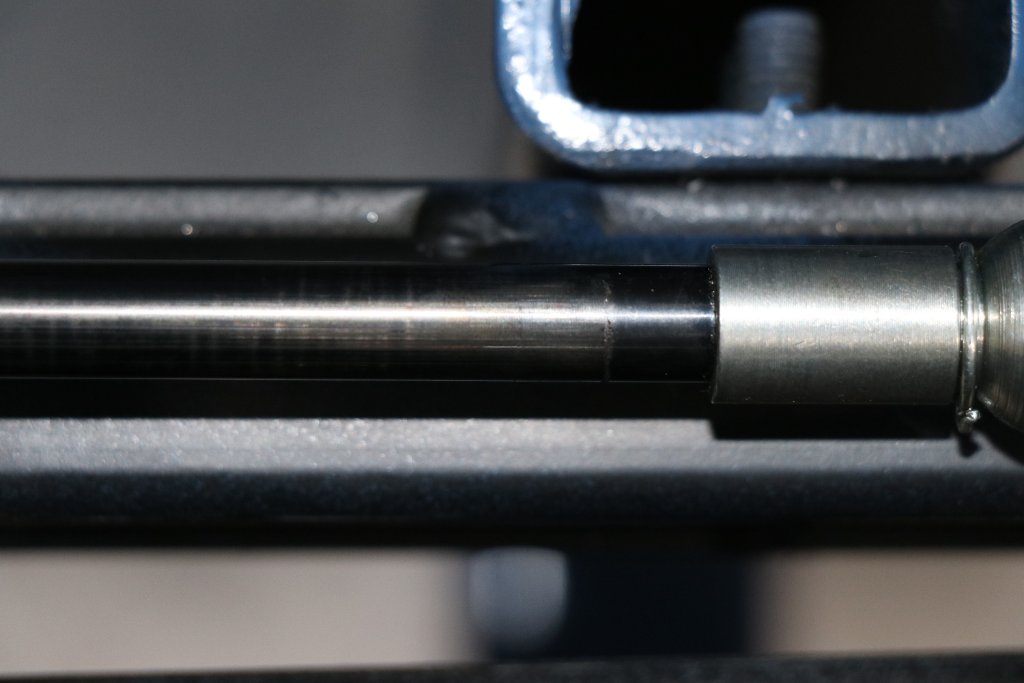

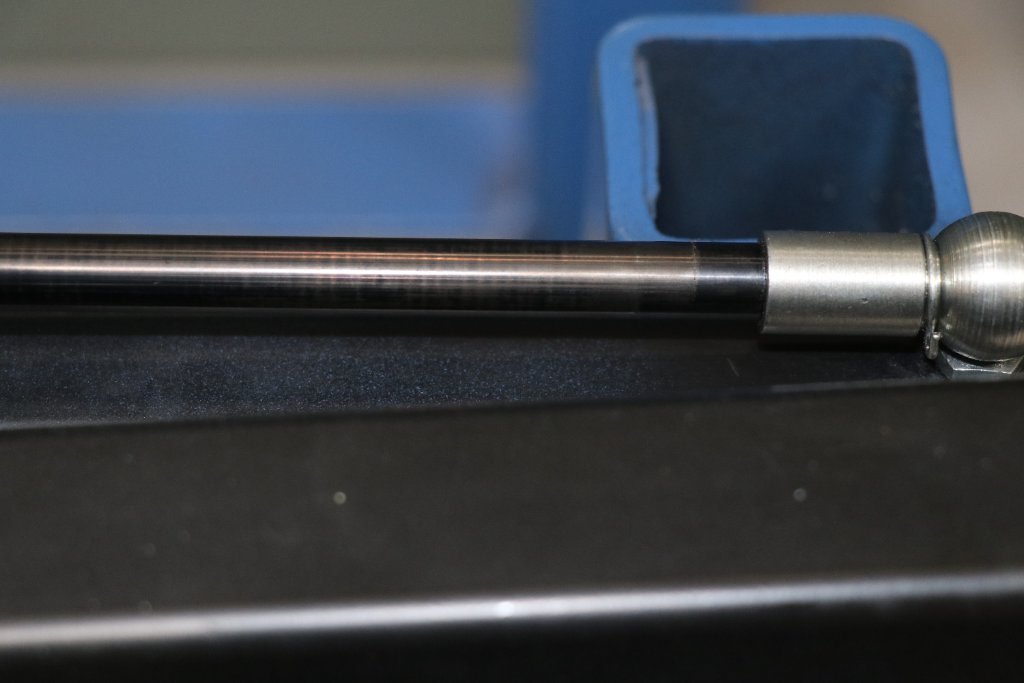

The images below show how the gas strut is set up and initial condition at the start of the test.

At 4,000 cycles, some flex between the chamber and ball joint end can be seen. The strut still has pressure in it, so the test is continued.

At 10,000 cycles, some marks are visible on the rod and the strut continues to work well.

At 20,000 cycles, the marks on the rod increase. A powder residue starts forming around the rod chamber.

At 40,000 cycles, the strut’s exterior condition is still good, aside from some cosmetic wear marks on the rod.

The strut’s gas pressure is measured, and it has approximately 61kg left from 65kg at the start of the test. The condition of the strut is good as it still works perfectly.

This concludes that the lifespan of this gas strut can last up to approximately 10 years. This is subject to the presence of foreign substances (dirt, oil, water), environment and usage of struts. Note that the gas pressure in a strut may also reduce over time.

**Disclaimer: Co-Mac has tested this product for Co-Mac’s purposes only and takes no responsibility for loss or damage caused by the use of this information.